Valve seat inserts are critical components for the operation of an engine and require a high level of expertise in both material handling and dimensional accuracy. For OEM manufacturers, we produce intake and exhaust valve seat inserts for four-stroke engines that are used, for example, in ships and power plants.

The specifications for valve seat inserts are in a class of their own, as they have to be able to endure extremely high temperatures. Heat-resistant materials are also expensive, which is why the manufacturing process has to be extremely well thought out to ensure that no material is wasted and that the products are profitable to manufacture.

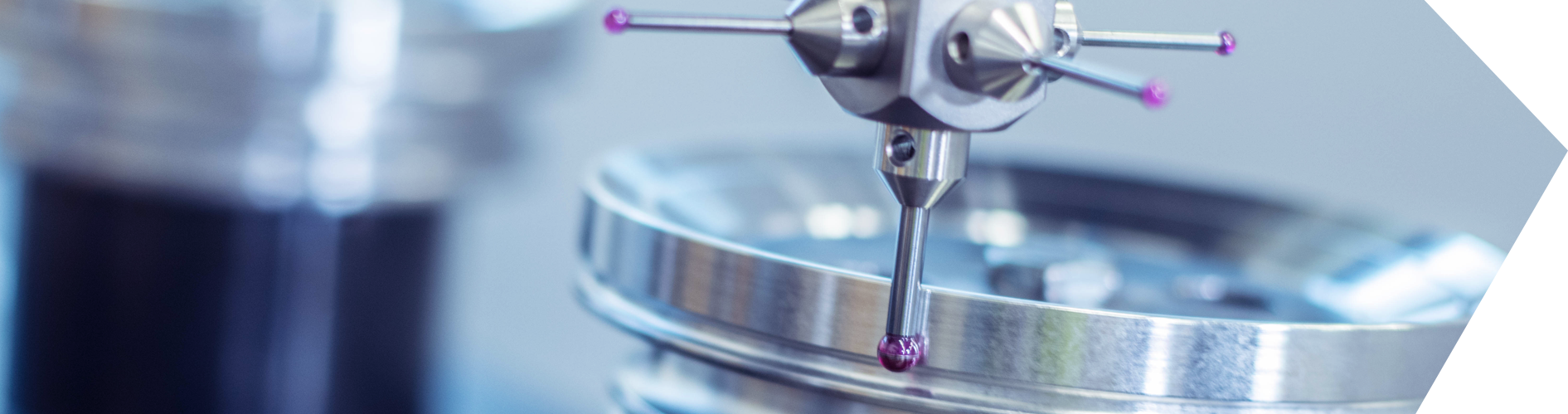

JTK Power Group specialises in manufacturing demanding pieces and we have more than 20 years of expertise in handling special materials. We inspect all the valve seat inserts we send out 100%. We check our exhaust valve seat inserts with a liquid penetrant inspection and 3D measuring equipment and our intake valve seat inserts with a manual gauge. In addition, we carry out extensive random checks.

The design of valve seat inserts usually starts with factors relating to their functionality. We are more than happy to help our customers with their design processes and drawings of valve seat inserts and we always bring along our own extensive expertise on the processibility of the product. When a piece is well designed, it is also as inexpensive as possible to make. We manufacture products according to the customer’s drawings and observe any non-disclosure agreements made.